When it comes to woodworking, choosing the right planer can make all the difference in your projects. A woodworking planer is essential for flattening and smoothing wood, allowing you to achieve that perfect finish. However, with so many options available, it’s important to consider a few key factors to ensure you select the one that meets your needs.

First, think about the type of projects you plan to tackle. If you’re a hobbyist working on smaller projects, a portable hand planer may suffice. These models are lightweight, easy to handle, and perfect for quick adjustments. On the other hand, if you’re working on larger pieces of lumber or need to produce consistent results for furniture or cabinetry, a bench-top or stationary planer would be more appropriate. These planers offer a broader cutting width and greater stability, making them ideal for serious woodworkers.

Next, consider the power of the planer. Planers are available in various horsepower ratings, and your choice will depend on how dense or thick your wood is. For softer woods, a less powerful model may be adequate. For hardwoods, however, look for a planer with more power to ensure it can handle tougher materials without bogging down. Additionally, check the feed rate and cutting speed to ensure the machine will get the job done efficiently.

Finally, take a look at the features that will make your woodworking experience smoother. Features such as depth adjustment, safety guards, and dust collection can significantly enhance usability and safety. Some modern planers even come with built-in digital displays for more precise settings. Don’t forget to read reviews and consult with fellow woodworkers to find the model that is most reliable and suits your crafting style.

Understanding Different Types of Planers

Hand Planers are classic tools that require no electricity, relying instead on the skill of the woodworker. These small, portable devices are great for fine-tuning the surface of your wood, making them ideal for detailed work. Hand planers are perfect for flattening edges and beveling corners. While they may require more physical effort and patience, many woodworkers appreciate the control and craftsmanship that come with using a hand planer.

Electric Planers, on the other hand, are designed for efficiency and speed. These power tools can quickly remove material, making them perfect for large projects or when you need to deal with rough lumber. With the ability to adjust the depth of cut, electric planers can help give you a smooth finish in less time. While they are user-friendly, it’s important to practice proper technique to avoid gouging the wood.

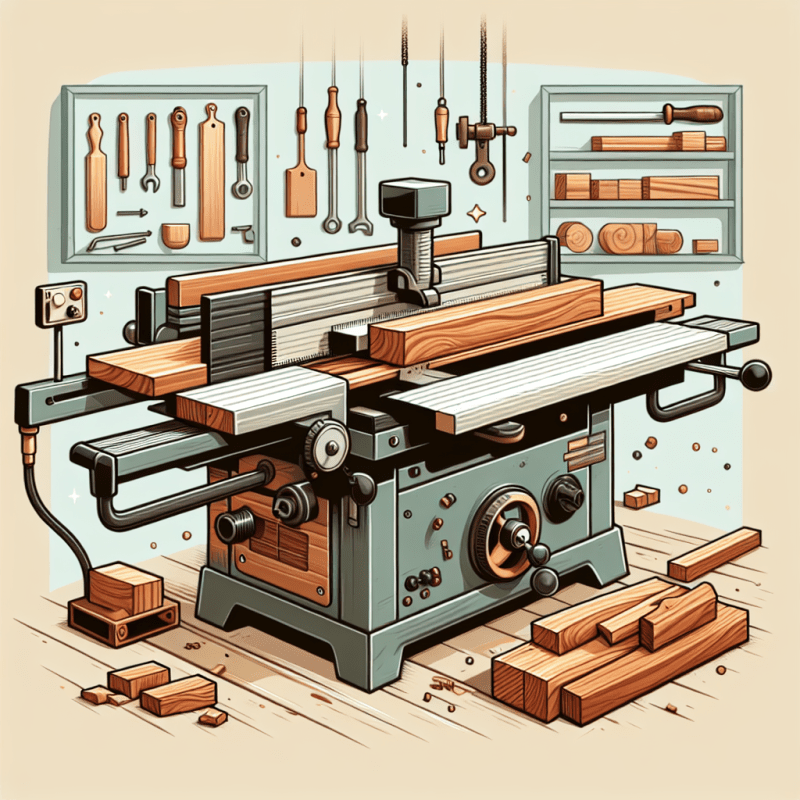

Finally, there are Thickness Planers, which are commonly found in professional woodworking shops. These machines are designed to create uniform thickness across the entire board, making them invaluable for preparing stock that will be glued together or need to match other pieces. Thickness planers can also help you achieve a smoother surface by taking off the rough or imperfect outer layer of wood. They are an investment but can significantly expand your woodworking capabilities.

Essential Techniques for Smooth Finishes

When it comes to achieving smooth finishes in woodworking, understanding essential techniques can make all the difference. Using a planer effectively is key to transforming rough lumber into beautifully flat, even surfaces. One of the most important aspects to remember is to always work with properly set blades. Dull blades can lead to tear-out and unevenness, creating more work for you down the line.

Next, it’s crucial to pay attention to feed rate. Feeding your wood too quickly can result in a choppy finish, while too slow may cause burning or chattering. Aim for a steady, moderate pace that allows the planer to do its job efficiently without compromising the quality of the cut. Additionally, check your material before you start. Ensure it is clean and free of any debris to avoid damaging the blades and to achieve the best surface possible.

One technique to enhance your finish is to make multiple passes with your planer. Start with a thicker cut to remove any major imperfections, and then gradually adjust the depth for finer, smoother passes. This method not only helps you achieve a flatter surface but also reduces the strain on your tool. Finally, consider the grain direction of the wood. Always plan with the grain to minimize tear-out and maximize the quality of your finish, leading to a more professional appearance in your final project.

Maintaining Your Planer for Longevity

Maintaining your planer is essential for ensuring its longevity and optimal performance. A well-cared-for tool not only works better but also saves you time and money in the long run. Regular maintenance can prevent common issues that may arise from neglect, allowing you to focus on your woodworking projects instead of repairs.

Start by keeping the blades sharp and free from damage. Dull blades can cause tear-out and an uneven finish, which means you’ll have to spend more time sanding and refining your work. Regularly inspect your blades for any nicks or dullness and replace or sharpen them as necessary. Additionally, ensure that the blade alignment is accurate. Misalignment can lead to uneven cuts and may put extra strain on the motor.

Another crucial aspect of maintaining your planer is to keep it clean. Wood dust and debris can accumulate in and around the machine, which may affect its performance and even pose a safety hazard. After each use, take a few moments to brush off any excess dust. Periodically, disassemble certain parts to remove deep-seated debris, ensuring that your planer continues to work smoothly.

Lastly, regularly check the condition of the belts and bearings. Wear and tear on these components can lead to decreased efficiency and can potentially cause serious damage to your equipment. If you notice any fraying or cracks in the belts or hear unusual noises coming from the bearings, it’s time to replace these parts. Staying ahead of these small issues can prevent larger, more costly repairs down the line.